In the great debate between DTF vs. sublimation, which printing method wins? 🥊

Well, it all comes down to one question: Which printing method fits your needs best?

We'll give you a full rundown of each printing method, including pros and cons, price, and what kind of person will benefit from each custom printing method.

Here’s what’s inside:

- DTF vs Sublimation Printing Methods: How Do They Compare?

- What is DTF Printing?

- What is Sublimation Printing?

- Choosing Between DTF Printing and Sublimation

- Frequently Asked Questions (FAQs)

If you're in a hurry, you can skim through the differences with this helpful chart we've compiled for you. 👇

DTF vs Sublimation Printing Methods: How Do They Compare?

|

Category |

DTF Printing |

Sublimation |

|

Pros 👍 |

Works on almost any fabric or material in any color |

Easy to start, affordable, makes natural-looking blended colors |

|

Cons 👎 |

Requires maintenance and constant use, more expensive to start |

Only works on polyester and poly blends, doesn’t show up on dark colors |

|

Ease of Use ✅ |

Must add powdered adhesive first, has a learning curve |

Simple: print and press |

|

Cost 💸 |

$3000 and up |

Under $500 |

|

Best for… 🏆 |

Businesses who print every day, t-shirt businesses |

Hobbyists and businesses alike |

What is DTF Printing?

DTF printing or direct-to-film printing is a method in which you print with specialized inks on film to create a transfer. While the ink is still wet, you apply curing powder to the design and then heat it until it melts into an adhesive layer.

DTF printing can be applied to almost any material. Suitable materials for DTF printing include cotton, nylon, polyester, treated leather, silk, and more. Just position the design adhesive-side-down and apply heat and pressure with a heat press machine.

The DTF printing method works well with t-shirts, tote bags, hats, and other garments.

What You Need for DTF Printing

Here's a summarized list of equipment and supplies you'll need to start your own DTF printing operation.

If you want to dive deeper into what DTF printing involves, check out our full-length guide to DTF.

Your design - Create a design using a favorite design tool or purchase a design on a shop like Etsy.

RIP software - This software, short for raster image processor, prepares your image for printing. (It should come with your printer bundle, so no need to purchase this separately.)

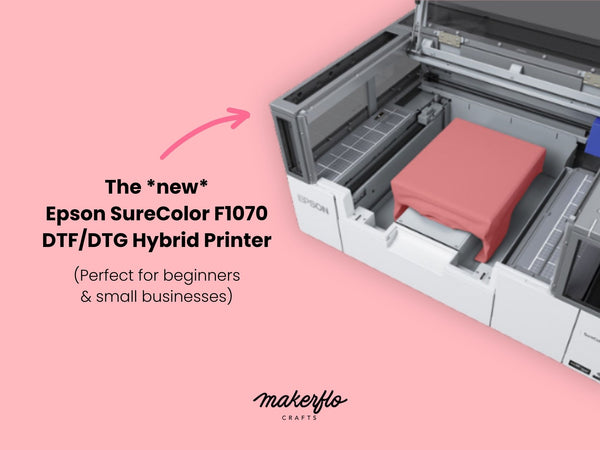

DTF printer - Your trusty workhorse that will create all your transfers for you. Epson has released a new entry-level DTF printer that also handles direct-to-garment printing, called the Epson SureColor F1070!

DTF ink - It's best to use the ink that's recommended by your printer manufacturer. Ink comes in CMYK and white. You'll either get ink bottles that you pour into the printer by hand or ink cartridges that you pop in (cartridges are easier but more expensive).

DTF film - Depending on your printer, you'll use film sheets or rolls.

DTF curing powder - This adhesive powder, also known as DTF powder or hot melt adhesive, melts down and dries into an adhesive layer on the back of your transfer.

DTF oven or heat source - You'll use this to cure the adhesive powder.

Safety precautions - You'll want an air purifier, proper eye and face protection, and a well-ventilated room to keep toxic fumes at bay. The adhesive used in DTF printing is extremely toxic and you don’t want to get it into your lungs.

Heat press - Finally, if you intend to transfer designs yourself, you'll need a heat press machine in the right size and shape for your garments.

The DTF Printing Process

- Prepare your design with RIP software, then print it out onto transfer film.

- While the ink is still wet, sprinkle curing powder over the design and shake off any excess powder. (Some DTF printers can do this for you.)

- Apply heat to cure the adhesive and let the DTF transfer dry.

- Once the transfer is dry, you can place it on your object and use a heat press to apply the transfer.

- Depending on your transfer instructions, you might peel the transfer while it's hot or wait until it cools first. Either way, you've got a nifty new DTF garment to enjoy!

Watch on TikTok

So why choose DTF printing over other methods? Let's run through all the benefits you get with this method:

Benefits of DTF Printing

- Because it uses white ink, designs show up beautifully on any color material, including dark-colored fabrics or surfaces

- DTF printing works with almost any type of fabric or surface, including natural materials like cotton and glass

- You can print vivid, high-fidelity designs

Downsides of DTF Printing

- It's notoriously hard to set up a DTF printer. Most printer owners say they had to go back and forth with customer support until they finally ironed out all the bugs.

- DTF printers are high-maintenance 💅. No, seriously, you have to print with them every day (or almost every day) to keep them from clogging and drying out. And you must clean the printhead every day before you start printing.

- There’s a big health risk with DTF adhesive powder. It can cause damage to your skin and respiratory system if you inhale it, so make sure you use proper face protection, add an air purifier, and keep your room well-ventilated when using curing powder.

- T-shirts and garments customized with DTF will have a plasticky feel to them because the transfer sits on top of the garment

- DTF printing costs more. Entry-level printers start around $3,000.

DTF Printing is Best For...

Business owners who are serious about DTF printing and want to print a high volume of garments. This isn't for hobbyists or on-and-off printing businesses.

If you won't be able to commit to the upkeep of this machine, it's not worth the investment.

As an alternative, you can buy pre-printed DTF transfers from other businesses and use them to customize your objects instead.

That said, if you're confident that you can run the printer regularly and aren't afraid of all the maintenance, this is a great investment for a digital printing business.

Check out the Epson F1070 DTF/DTG Hybrid Printer if you're ready to get started with DTF printing! 👇

Now let's take a look at sublimation printing.

What is Sublimation Printing?

Sublimation printing is a method in which you print designs onto sublimation paper with sublimation ink.

Unlike DTF, sublimation printing doesn't require any adhesive. All the magic is in the inks themselves.

Watch on TikTok

Here's how sublimation printing works:

When you apply heat to sublimation transfers with an oven or heat press, the ink sublimates—in other words, turns into a vapor—and the gas particles sink into your fabric and embed themselves permanently there.

What you get is a beautiful, vibrant design with gorgeous blending and absolutely no texture left on top of the material.

Like this mug, for example:

If you want to learn more about sublimation, check out our beginner's guide to sublimation printing.

This works on any fabric made of at least 65% polyester or objects with a polyester coating. This includes tumblers, mugs, pens, keychains, and more.

For more fun projects you can make with a sublimation printer, check out our ultimate list of sublimation ideas.

Now let's talk about what you need for sublimation printing.

What You Need for Sublimation Printing

Your design - You can create a design with your favorite design program or buy a sublimation design online. (You don't need a RIP software to prepare the design—it's good to go!)

Sublimation printer - This is a printer designed to print with sublimation ink. We recommend the Epson SureColor F170 for beginners (it retails for just under $500), but you can learn more in this guide to sublimation printers. Some people convert inkjet printers for sublimation, but this can lead to clogging and other issues, so we don’t recommend it.

👉 Read More: Why THIS is the Best Epson Printer for Sublimation

Sublimation ink - These inks (aka sublimation dyes) vaporize at a certain temperature (in the chemical process called sublimation). You can't use regular inks for sublimation.

👉 Read More: 7 Best Sublimation Inks for Out-Of-This-World Color

Sublimation paper - A dedicated sublimation paper is the special transfer paper used for sublimation.

👉 Read More: Best Sublimation Paper for Crafters & Businesses (Compared)

Heat-resistant tape - You'll use this to tape down designs, especially for round items like cups and tumblers

Heat-resistant gloves - You'll need this to handle hot items after baking them

Plastic gloves - These are optional, if you want to keep fingerprints off your items when preparing them to transfer

Safety precautions - We recommend having an air purifier or keeping your room well-ventilated when sublimating

An oven or heat press - You'll use a sublimation oven or heat press to apply sublimation transfers to your object, depending on the size and shape of the item

The Sublimation Printing Process

- Print your design using a sublimation printer. (The printer should automatically print the image in reverse. If not, adjust your print settings and print again.)

- Tape the design onto your object so there are no gaps between the transfer and the object beneath.

- Use a heat press or sublimation-friendly oven to apply heat to the object.

- Peel off the transfer and enjoy your design!

Watch on TikTok

So why choose sublimation over other methods? Let's take a look at the pros and cons:

Benefits of Sublimation Printing Using A Sublimation Printer

- Because sublimation ink vaporizes, you can create an airbrush print quality or watercolor effect with beautiful blends that you don't get with other transfers

- With sublimation printing, the ink goes into the fabric rather than sitting on the surface, so it doesn't leave any print texture on top of the material

- Sublimation equipment and materials are more affordable than DTF equipment

- You don't need to maintain the printer like you would with a DTF printer—it's better suited for hobbyists and small businesses alike

- It's fast to print, and you don't need to apply any adhesive—the transfer is ready as soon as it dries

Downsides of Sublimation Printing

- Sublimation prints don't use white ink, so designs won't show up well on dark-colored materials—that's why most sublimation blanks are white

- Sublimation printing only works on synthetic materials like polyester, polyester blends, or items sprayed with a sublimation coating, so you're limited in the items you can customize

So who should choose sublimation printing?

Sublimation Printing is Best For...

Hobbyists and business owners alike, anyone who wants to print and customize their own items without the commitment of daily digital printing and lots of maintenance.

Sublimation printing is also the best crafting method for hard objects like tumblers, mugs, sippy cups, and more.

Epson® F170 Sublimation Starter Kit

Grab this handy starter kit featuring our best-selling sublimation printer!

Choosing Between DTF and Sublimation Printing Methods

We hope this article has helped you find the difference between DTF printing and sublimation printing and weigh the pros and cons to find the right method for your crafting hobby or business.

Which one sounds right for you? We'd love to hear from you!

What to do next? Well, in choose-your-own-adventure-style, we invite you to dive even deeper into your printing method of choice between DTF printing and sublimation:

- What is DTF? The Crafter's Guide to Direct-to-Film Printing

- What is Sublimation? The Essential Guide for Crafters

And if you'd like to get even more support from the MakerFlo team and thousands of other crafters, make sure to join our MakerFlo Facebook Community. We'll see you there!

Frequently Asked Questions (FAQs)

Which sublimation printers are best for small businesses?

We recommend the Epson SureColor F170. We have a sublimation starter kit that includes everything you need to get started, including the printer and all supplies. Others swear by the Sawgrass lineup of printers. You can learn more in our guide to sublimation printers.

Does sublimation last longer than DTF?

Both of them are very durable and can stand the test of time, but you will need to take care of each item. T-shirts personalized using sublimation printing should be washed inside out with cold water and no more than a gentle detergent, for example. Clothing customized using DTF printing can last a long time, but the transfers can crack or peel with extreme wear and tear or too-hot washes.

What is the difference between sublimation and DTF printing transfers?

Sublimation inks vaporize with heat and sink into the surface of your material. DTF printing transfers have an adhesive layer that melts and adheres to your fabric. For more differences, read the full article above!

Can DTF be used for sublimation?

DTF printers won't make sublimation transfers unless you convert them into sublimation printers. Your best bet is to use a specialized printer and supplies for the type of printing you want to do.

How long do DTF transfers last?

DTF transfers last a very long time. They're stretchy and resistant to cracking. To extend the life of your DTF garment, wash in cold or lukewarm water on a gentle cycle.